Carbon Monoxide (CO) is a colorless, odorless gas formed when carbon in fuel is not burned completely (incomplete combustion). Vehicle exhaust contributes about 60 percent of all CO emissions in the United States. Construction equipment and boats contribute about 22 percent of all CO emissions nationwide. Higher levels of CO generally occur in areas with heavy traffic congestion. In cities, 95 percent of all CO emissions may come from motor vehicle exhaust. Other sources of CO emissions include industrial processes (such as metals processing and chemical manufacturing), residential wood burning, and natural sources such as forest fires. Woodstoves, gas stoves, cigarette smoke, and unvented gas and kerosene space heaters are sources of CO indoors. The highest levels of CO in the outside air typically occur during the colder months of the year when CO automotive emissions are greater and nighttime inversion conditions are more frequent. In inversion conditions the air pollution becomes trapped near the ground beneath a layer of warm air. Overexposure to carbon monoxide can cause asphyxiation and death.

Carbon Monoxide (CO) is a colorless, odorless gas formed when carbon in fuel is not burned completely (incomplete combustion). Vehicle exhaust contributes about 60 percent of all CO emissions in the United States. Construction equipment and boats contribute about 22 percent of all CO emissions nationwide. Higher levels of CO generally occur in areas with heavy traffic congestion. In cities, 95 percent of all CO emissions may come from motor vehicle exhaust. Other sources of CO emissions include industrial processes (such as metals processing and chemical manufacturing), residential wood burning, and natural sources such as forest fires. Woodstoves, gas stoves, cigarette smoke, and unvented gas and kerosene space heaters are sources of CO indoors. The highest levels of CO in the outside air typically occur during the colder months of the year when CO automotive emissions are greater and nighttime inversion conditions are more frequent. In inversion conditions the air pollution becomes trapped near the ground beneath a layer of warm air. Overexposure to carbon monoxide can cause asphyxiation and death.

Many do-it-yourself projects take place inside the home and may involve rented tools or cramped workspaces. This can lead to eye damage. Read and follow safety guidelines on tools. Wear well-fitting safety eyewear to provide protection from impact. Consider the hazards specific to the job to determine whether goggles or even respiratory protection are required, as in the case of high-particulate projects like sanding drywall.

Keep single-use eyewash bottles on hand at home to safely flush nuisance irritants such as dust and sand.

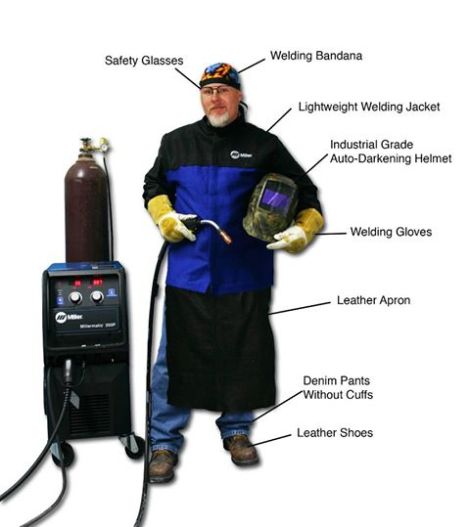

Hot work is any process that can be a source of ignition when flammable material is present or can be a fire hazard regardless of the presence of flammable material in the workplace. Common hot work processes are welding, soldering, cutting and brazing. When flammable materials are present processes such as grinding and drilling become hot work processes. Hot work can be dangerous due to the potential for sparks to come in contact with flammable or combustible materials or combustible dusts. Many locations require a permit checklist for performing hot work.

The Canadian Centre for Occupational Health and safety offers these recommendations for safe hot work:

Make sure that all equipment is in good operating order before work starts.

Inspect the work area thoroughly before starting. Look for combustible materials in structures (partitions, walls, ceilings).

Sweep clean any combustible materials on floors around the work zone. Combustible floors must be kept wet with water or covered with fire resistant blankets or damp sand.

Use water ONLY if electrical circuits have been de-energized to prevent electrical shock.

Remove any spilled grease, oil, or other combustible liquid.

Move all flammable and combustible materials away from the work area.

If combustibles cannot be moved, cover them with fire resistant blankets or shields. Protect gas lines and equipment from falling sparks, hot materials and objects.

Block off cracks between floorboards, along baseboards and walls, and under door openings, with a fire resistant material. Close doors and windows.

Cover wall or ceiling surfaces with a fire resistant and heat insulating material to prevent ignition and accumulation of heat.

Secure, isolate, and vent pressurized vessels, piping and equipment as needed before beginning hot work.

Inspect the area following work to ensure that wall surfaces, studs, wires or dirt have not heated up.

Vacuum away combustible debris from inside ventilation or other service duct openings to prevent ignition. Seal any cracks in ducts. Prevent sparks from entering into the duct work. Cover duct openings with a fire resistant barrier and inspect the ducts after work has concluded.

Post a trained fire watcher within the work area during welding, including during breaks, and for at least 30-60 minutes after work has stopped. Depending on the work done, the area may need to be monitored for longer (up to 3 hours) after the end of the hot work.

Eliminate explosive atmospheres (e.g., vapours or combustible dust) or do not allow hot work. Shut down any process that produces combustible atmospheres, and continuously monitor the area for accumulation of combustible gases before, during, and after hot work.

If possible, schedule hot work during shutdown periods.

Comply with the required legislation and standards applicable to your workplace.

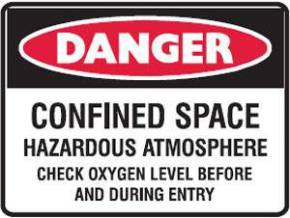

OSHA defines a hazardous atmosphere as “an atmosphere that may expose employees to the risk of death, incapacitation, impairment of ability to self-rescue (that is, escape unaided from a permit space), injury, or acute illness from one or more of the following causes:

(1) Flammable gas, vapor, or mist in excess of 10 percent of its lower flammable limit (LFL);

(2) Airborne combustible dust at a concentration that meets or exceeds its LFL;

NOTE: This concentration may be approximated as a condition in which the dust obscures vision at a distance of 5 feet (1.52 m) or less.

(3) Atmospheric oxygen concentration below 19.5 percent or above 23.5 percent;

(4) Atmospheric concentration of any substance for which a dose or a permissible exposure limit is published in Subpart G, Occupational Health and Environmental Control, or in Subpart Z, Toxic and Hazardous Substances, of this Part and which could result in employee exposure in excess of its dose or permissible exposure limit;

NOTE: An atmospheric concentration of any substance that is not capable of causing death, incapacitation, impairment of ability to self-rescue, injury, or acute illness due to its health effects is not covered by this provision.

(5) Any other atmospheric condition that is immediately dangerous to life or health.”

NOTE: For air contaminants for which OSHA has not determined a dose or permissible exposure limit, other sources of information, such as Material Safety Data Sheets that comply with the Hazard Communication Standard, section 1910.1200 of this Part, published information, and internal documents can provide guidance in establishing acceptable atmospheric conditions.

A hazardous atmosphere can be determined by the use of a 4-gas meter, which usually checks for oxygen content (O2), carbon monoxide (CO), hydrogen sulfide (H2S), and lower explosive limit (LEL). If a hazardous atmosphere is determined, entry is not permitted. You must determine other means to eliminate the hazard, such as through ventilation. Upon entry, an attendant must be positioned at the opening of the space to continually check the atmosphere and to remain in contact with the entrants.

WHAT IS AN ACCIDENT ?

ACCIDENT CAUSES

WHAT IS ACCIDENT INVESTIGATION ?

- Provide information needed to determine injury rates, identify trends or problem areas, permit comparisons and satisfy Workers Compensation requirements;

- Identify, without placing blame, the basic causal factors that contributed directly or indirectly to each accident;

- Identify deficiencies in management systems;

- Suggest corrective action alternatives for a given accident;

- Suggest corrective action alternative.

WHY ACCIDENT INVESTIGATION?

- Legal Requirement

- Establish Causes

- Prevent Recurrences

- Accurate record (courts & enquiries)

- Statistical data base

THE INVESTIGATOR’s QUALIFICATIONS

- Technical Knowledge

- Objectivity

- Analytical approach to problems

- Familiarity with the job, process or operation

- Tact in communicating

- Intellectual honesty

- Inquisitiveness & curiosity

HOW TO INVESTIGATE

Determine the Facts :

- Visit accident scene,

- Take samples,

- Visual records,

- Preserve accident items,

- Identify people involved,

- Interview witnesses,

- Review information

- What was the exact injury or damage ?,

- What was the cause ?,

- What event immediately preceded the damaging event ?,

- What happened before that ?,

- What happened even before that ?,

- What happened in between ?,

- What else was going on at the time of the accident ?,

- Was anyone else involved ?,

- Interview witnesses.

- Put at ease,

- Assure “no blame”,

- Ask witness to relate their account of the accident,

- Listen carefully,

- Ask questions – reinforce,

- Repeat if necessary,

- Ask witness for suggestions for future avoidance,

- Encourage further contact, Be polite and thank the witness.

- Accuracy & completeness of information,

- Clarity & completeness of of the description of the sequence of events leading up to the accident,

- Correct identification of all causal factors,

- Clarity & completeness of all causal factors,

- Recommendations made for corrective actions to reduce or eliminate the probability of recurrence of a similar accident,

- Recommendations for corrective actions to improve management system,

- Timelines – specific time periods, monitoring and responsibilities,

- Proper review and sign off.

- Accident investigation Form

- Witness Statements & Records of Interview

- Checklists: Victim(s), Witnesses, Environment & Locations, Equipment & Parts, Documentation

- Accident/Incident Record

The effects of Accidents

- On the Victim

- On the Supervisor

- On the Institution

- On the Nation

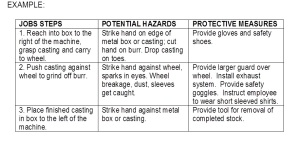

What is the difference between Risk Assessment and Job Safety Analysis?

Posted: February 11, 2013 in UncategorizedJSA is a careful study for each step in a job, identifying the safety and health hazards at each step individually and classifying the the severity and probability (H,M,L) for each hazard , identifying appropriate controls to eliminate or reduce each hazard.

Risk Assessment is evaluation of a hazard in an incident potential matrix and determine relative risk of different hazards as a way of prioritizing.

What is Safety

Posted: February 11, 2013 in UncategorizedTags: safe, Safety Definition, safety meaning, What is Safety, What is Safety Meaning

There are many interpretations of the word “safety” that depend on the context of where it is actually used. The most common interpretation is

“The condition of being safe from undergoing or causing hurt, injury, or loss”.

The way to define Safety:

- Safety is the condition of avoiding causing or feeling hurt, injury or loss. An example of such a meaning would be “I feel safe around him”, meaning that a person feels like she is avoiding feeling hurt or getting injured when another person is being present, who provides that feeling of protection.

- “Safety” can be used to name an object whose whole purpose is to prevent or discourage operation of a dangerous weapon or machine without explicit intent to do so. An example usage is “He disabled the safety on the pistol before he shot 5 rounds at the target”.

- Safety is a situation in football in which a member of the offensive team is tackled behind its own goal line that counts two points for the defensive team.

- “Safety” can reffer to a situation in football that is similar to “own goal” in other team sports. It happens when an opponent in possesion of the ball is tackeled in his own end zone. For example, “A safety is usually a team’s last line of defense in football”

Job Safety Analysis (JSA)

Posted: February 11, 2013 in UncategorizedTags: identify hazard, Job Safety Analysis, job task, job tasks, JSA, work environment

Definition: A systematic method of identifying hazards & control measures to safely perform a specific task.

WHAT IS JOB SAFETY ANALYSIS

A JSA is a technique of screening job tasks as a way to identify hazards before they occur (or) It is a procedure by which pertinent information is obtained about the job. i.e. It is a detailed and systematic study of information relating to the operations and responsibilities of a specific job. It focuses on the relationship between the worker, the task, the tools and the work environment. After identifying hazards, you can take steps to eliminate or reduce the hazard to an acceptable level.Specially,What the worker does; how he gets it done, why he does it ,skill ,education and training required , relationship to other jobs, Physical demands, environmental conditions etc…

WHY CONDUCT A JOB SAFETY ANALYSIS

- To become aware of all the hazards associated with each position in your organization.

- To prevent work related deaths, injuries, or illness by eliminating or controlling hazards identified.

- To ensure all employees have the proper job procedures to ensure their safety.

- To ensure all employees have the training, equipment, and supplies to do their jobs safely

-

It helps in establishing clear cut standards which may be compared with the actual contribution of each individual.

BENEFITS OF JSA

- Training of new employees

- Accident investigation tool

- Supervisor evaluation tool

- Consistency in training

- Injury reduction

- Organization and Manpower Planning

- Recruitment, Selection

- Wage and Salary Administration

- Job Re-Engineering

- Employee Training and Management Development

- Performance Appraisal

- Health and Safety

- Evaluate existing jobs

- Prioritize jobs needing re-design

- Ties in closely with other job analyses

THE PROCEDURE